ACR-700 Simulator

ADVANCED CANDU 700 MWe REACTOR

NPP SIMULATOR

The purpose of the 700 MW(e) advanced CANDU reactor (ACR-700) NPP

simulator is educational — to provide a training tool for university

professors and engineers involved in teaching topics related to the second

generation advanced CANDU reactor. Nuclear engineers, scientists and trainers

familiar with the conventional CANDU 6 would

find this simulator useful in broadening their understanding of ACR

transients, power plant dynamics, and passive safety features. As such, this

simulator is currently used in the IAEA Workshop "NPP Simulators for

Education".

The simulator has sufficient

simulation fidelity to provide realistic ACR plant responses during normal operations and

accident situations. It also has a user-machine interface that mimics the

actual control panel instrumentation, including the plant display system. More importantly,

it allows user’s interactions with the simulator during

the operation of the simulated ACR plant.

The current configuration of the Simulator is able to respond to the

operating conditions normally encountered in power plant operations, as well

as to many malfunctions, as summarized in the following Table.

|

System |

Simulation Scope |

Display Pages |

Operator Controls |

Malfunctions |

|

REACTOR

CORE |

*

Neutron flux levels over a range of 0.001 to 110% full power, 6

delayed neutron groups * Decay heat (3 groups)

* All reactivity control devices – zone control rods (ZCU),

absorber rods (MCA); gadolinium control.

* Xenon/Iodine poison

* Spatial kinetic simulated for 18 reactor zones, enabling display

of flux tilt.

* Reactor Regulating System (RRS)

* Reactor Shutdown System - SDS1

|

ACR Reactor Power control

ACR Control Rods & SD rods

ACR Trip parameters

|

* Reactor power setpoint and rate of change (input to control

computer)

* Manual control of reactivity devices - control rods (ZCU),

absorber rods (MCA) and gadolinium addition/removal

* Reactor trip

* Reactor setback

* Reactor stepback

|

* Reactor setback and stepback fail

* One bank of MCA rods drop into the reactor core

* All MCA rods “stuck” to manual

|

|

REACTOR COOLANT (light water) |

* Main circuit coolant loop with four pumps, two steam

generators, six equivalent “lumped” reactor coolant channels.

* Fuel and coolant heat transfer simulated for 18 reactor zones

* Pressure and inventory control which includes pressurizer,

bleed condenser, feed & bleed control, and pressure relief, coolant

makeup.

* Operating range is from zero power hot to full power |

ACR Reactor Coolant System

ACR Coolant Inventory & Pressurizer

ACR Inventory Control

ACR Pressure Control |

* Coolant heat transport system (HTS) pumps *Coolant

makeup pumps

* Pressurizer pressure control: heaters; spray; pressure

control valve; relief valve

* Pressurizer level control by regulating coolant feed & bleed

flow via control valves.

* Isolation valves for coolant feed and bleed |

*Pressurizer pressure relief valve fails open * Coolant

feed valve fails open

* Coolant bleed valve fails open

*Pressurizer heaters #2 to # 6 turned "ON" by malfunction

* Reactor inlet header break

* Loss of one HTS pump

* Loss of two HTS pumps in one loop |

|

STEAM & FEED-WATER |

* Boiler dynamics, including shrink and swell effects *

Steam supply to turbine and reheater

* Turbine by-pass to condenser

* Extraction steam to feed heating

* Steam generator pressure control

* Steam generator level control

* Boiler feed system |

ACR Feedwater and Extraction Steam |

* Feed pump on/off operation

* Boiler level controller mode: Auto or manual

* level control setpoint changes during Auto operation

* Level control valve opening during manual operation

* Extraction steam valves opening

|

* All level control isolation valves fail closed

* One level control valve fails open

* One level control valve fails closed

* Main feedwater pump trips

* All main steam safety relief valves (MSSV) open

* Steam header break

* Steam flow transmitter failure

|

|

TURBINE-GENERATOR |

* Simple turbine model * Mechanical power and generator

output are proportional to steam flow

* Speeder gear and governor valve allow synchronized and

non-synchronized operation

*Turbine steam bypass |

ACR Turbine-Generator |

* Turbine trip

* Turbine run-back

* Turbine run-up and synchronization

* Condenser steam discharge valves (CSDV

* Atmospheric steam discharge valve (ASDV) |

* Turbine spurious trip

*Condenser steam discharge valves (CSDV) failed closed |

|

OVERALL UNIT |

* Fully dynamic interaction between all simulated systems

* Overall unit power control with reactor leading mode; or

turbine leading mode

* Unit annunciation & time trends

* Computer control of all major system functions |

ACR Plant Overview

ACR Control Loops

ACR MW Demand SP & SGPC |

* Reactor power setpoint and rate entry in reactor-lead

mode.

* Turbine load setpoint (MW) and loading rate entry in

turbine-lead mode |

|

|

SAFETY SYSTEM |

* Emergency Core Cooling System (ECC) * Simple Model for

containment. |

ACR Passive Core Cooling |

|

Reactor inlet header break |

The interaction between the user and the Simulator is via a combination of

monitor displays, mouse and keyboard. Parameter monitoring and operator controls

implemented via the plant display system at the generating station are

represented in a virtually identical manner on the Simulator. Control panel

instruments and control devices, such as push-buttons and hand-switches, are

shown as stylized pictures, and are operated via special pop-up menus and dialog

boxes in response to user inputs.

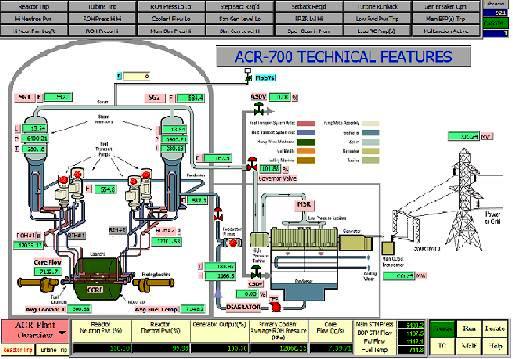

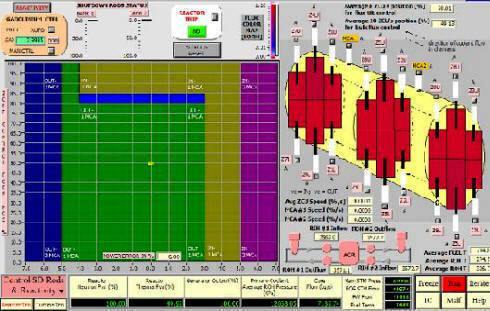

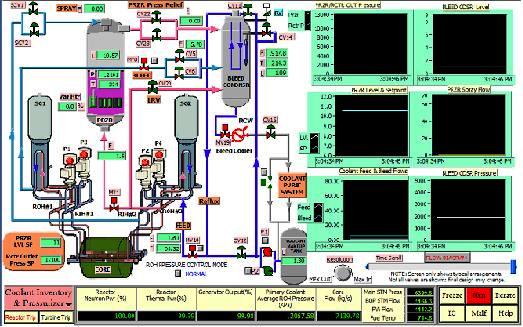

Below are samples of the ACR-700 Simulator screens:

ACR Overview Screen

ACR Control Rods and Shutdown Rods Screen

ACR Coolant & Pressurizer Screen

|

CTI

SIMULATION

INTERNATIONAL

CTI

SIMULATION

INTERNATIONAL CTI

SIMULATION

INTERNATIONAL

CTI

SIMULATION

INTERNATIONAL